Materials and production of sintered filters

Sintered filters are being used in an increasing number of applications. These filters are made from bronze, stainless steel or polyethylene. Sintered filters are characterized by close tolerances, a good price/quality ratio and a broad filter range of 0.5 to 200µm for SS and 8 to 100µm for bronze.

Production process bronze sintered filters

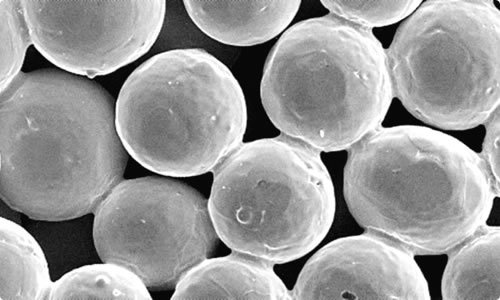

Bronze sintered filters are made from spherical bronze powder. The form, size and distribution of the powder are important parameters which affect the filter's properties.

Bronze sintered filters are produced using the gravity sintering method. The bronze powder is placed in a mold and sintered.

During sintering, the powder particles are fused to one another at temperatures well below the melting point of the material. This process gives the highly porous filters their characteristic shape and properties.

After sintering, the size and position of the pores are mechanically fixed. The powder particles also form a rigid whole. This gives the filters a strength, form and stability equal to those of a bronze component.

Production process stainless steel sintered filters

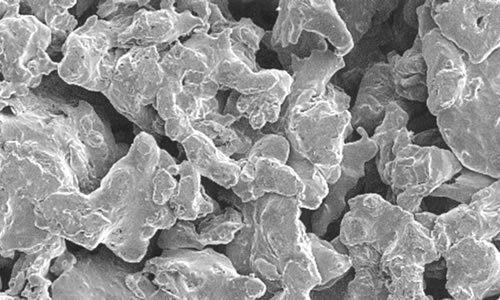

Stainless steel sintered filters are made from any metallurgical material that is produced as a powder. The filter's ultimate properties are influenced by the shape, size and distribution of the powder.

The most common materials are highly alloyed stainless steel types, but there are also nickel-based stainless steel varieties and titanium.

During the production of stainless steel sintered filters, the powder is compressed into a mold to create a solid, brittle component. The pore size can be determined by the powder that is chosen and the pressing force that is applied.

During sintering, the powder particles are fused to one another at temperatures well below the melting point of the material. This process gives the highly porous filters their characteristic shape and properties.

After sintering, the size and position of the pores are mechanically fixed. The powder particles also form a rigid whole. This gives the filters a strength, form and stability equal to those of a metal component.

Material SIKA-B

SIKA-B are sintered porous bronze parts produced from spherical bronze powder.

These items are highly corrosion resistant, are characterized by a high structural stability and strength, they are self-supporting and suitable for high pressure differentials.

Material SIKA-R

SIKA-R are sintered porous SS parts produced from irregularly shaped SS powder, generally AISI 316L.

They are stronger than bronze filters because of the powder's irregular shape. They are also suitable for higher temperatures.

Specifications and materials of sintered filters

| Specifications | |||||

|---|---|---|---|---|---|

| Group | Material | W. no. |

Max. Temp. |

Max. Temp. | Key words |

| Bronze | CuSn12 | 2.1052 | 300 | 250 | For hydraulics and pneumatics |

| High-alloyed materials | AISI 304L | 1.4306 | 540 | 400 | (The) standard for applications in the food industry |

| High-alloyed materials | AISI 316L | 1.4404 | 540 | 400 | (The) standard for applications in the food industry |

| High-alloyed materials | AISI 904L | 1.4539 | 600 | 500 | Resistant to sulphuric, phosphoric and hydrochloric acid |

| High-alloyed materials | AISI 310 | 1.4841 | 800 | 600 | Heat-resistant |

| High-alloyed materials | FeCrAI | 1.4767 | 900 | 900 | Heat-resistant |

| Nickel alloys | Hastelloy C 22 | 2.4602 | 650 | 650 | Resistant to corrosion from different aggressive media. Sustained temperatures of >400 are possible. |

| Nickel alloys | Hastelloy C 276 | 2.4819 | 650 | 600 | Resistant to corrosion from different aggressive media. Sustained temperatures of >400 are possible. |

| Nickel alloys | Hastelloy X | 2.4665 | 925 | 925 | Resistant to corrosion from different aggressive media. Sustained temperatures of >400 are possible. |

| Nickel alloys | Inconel 600 | 2.4816 | 650 | 650 | Resistant to corrosion from different aggressive media. Sustained temperatures of >400 are possible. |

| Nickel alloys | Inconel 625 | 2.4856 | 650 | 600 | Resistant to corrosion from different aggressive media. Sustained temperatures of >400 are possible. |

| Nickel alloys | Monel 400 | 2.4360 | 500 | 500 | Resistant to media containing CI |

| Titanium | Ti | - | 500 | 500 | Medicines, acids, electrolysis |

Product finder sintered filters

Find the right sintered filters with the online product finder. Enter the values you need and the product finder will calculate the pressure drop and the filter surface. This way you know which type of sintered filter is most suitable for your application.

Need technical advice?

Are you looking for sintered filters or do you want more information about the possibilities of customization? Call us on +33 (0)3 72 39 51 51 or send an email to info@thn.fr. We are happy to help.

Contact us