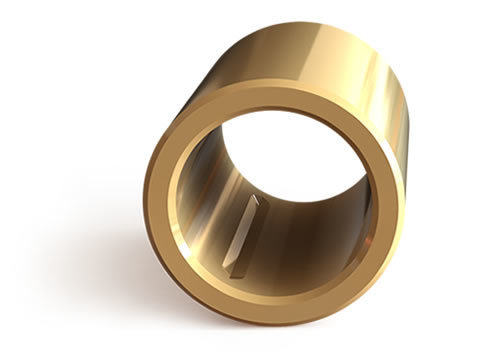

Solid bronze bearings

Good in severe and contaminated conditions

Solid bronze bearings are highly suited to demanding applications in challenging environments. This makes the solid bronze bearings ideal for a wide variety of applications.

Advantages of solid bronze bearings

Main advantages of solid bronze bearings include:

- Not affected by impurities

- Suitable for corrosive environments

- Suitable for impact loads and vibrations at low speeds

- Has a groove to retain the lubricant

Applications of solid bronze bearings

Solid bronze bearings are ideal for applications involving oscillatory movements, both axial and radial. Common applications are:

- Offshore

- Dredging industry

- Mechanical engineering

- Elevators

Materials

Solid bronze bearings are made from CuSn7Zn4Pb7 continuously cast bronze. This material is 85% copper and has very good sliding characteristics. All the surfaces of this plain bearing are machined.

Many other alloys are also available beside the standard material. Most common among these are CuAl10Ni, CuSn10 and CuSn12.

Lubrication

Solid bronze bearings are normally lubricated with grease, but oil is also used in exceptional applications. A good quality lubricant will ensure that friction and wear will be reduced by the forming of a film between the plain bearing and the shaft. For heavily contaminated applications we recommend sealing off the bearing. This will protect both the bearing and the lubricant.

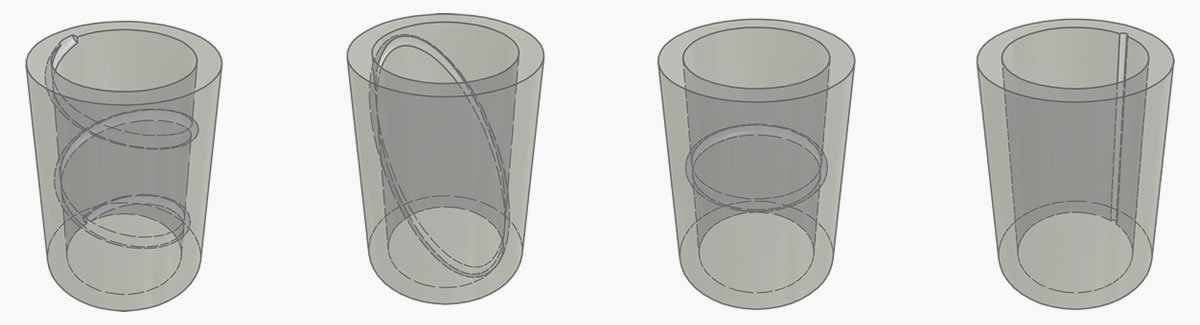

All solid bronze bearings with an inside diameter of 14 mm or more are provided with an axial lubrication groove.

Lubrication groove options

Specification overview of solid bronze bearings

| Specification overview | |

|---|---|

| Properties | TB |

| Max. load (Dyn/stat), N/mm2 | 25 / 45 |

| Max. sliding speed m/s | 0.5 |

| Max. PV value N/mm2 x m/s | 2.8 |

| Temperature range, oC | +250 (depending on type of lubricant) |

| Shaft tolerance | e7 - e8 |

| Housing tolerance | H7 |

| Shaft roughness | Ra ≤ 1.0 |

| Shaft hardness | > 165 HB |

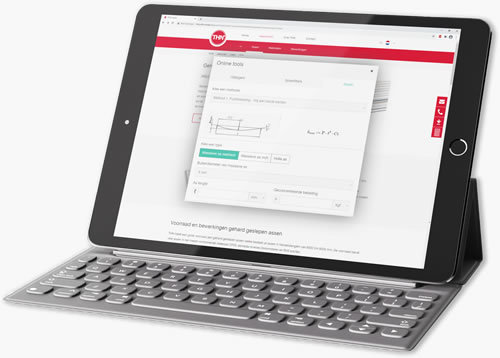

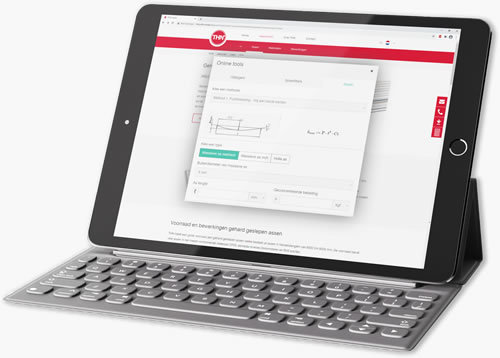

Product finder plain bearings

Find the right plain bearings for your applications with the online product finder. Enter the values for the load, speed, inner diameter and length. You immediately get an overview of the type of plain bearings that match the entered values. This way you know exactly which plain bearings are most suitable for your application.

Need technical advice?

Are you looking for plain bearings and do you want to contact a technical advisor? Call us on 03 72 39 51 51 or send an email to info@thn.fr. We are happy to help.

Contact us